How can we help you?

Please get in contact with us to find out more about ECFP and whether we can help you.

The interface between two liquids is vital to the production and stability of many foods and consumer formulations but measuring how interfaces flow is a delicate task. Researchers from ECFP and the Soft Matter Physics group at the University of Edinburgh have developed a new interfacial rheology technique to test how interfaces flow without direct mechanical contact. This matches how interfaces in consumer products are indirectly affected by the flow of liquid as, e.g., as skin cream is applied.

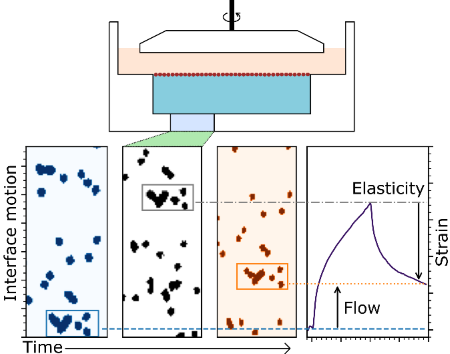

Conventional interfacial shear rheology attaches a mechanical probe to the interface, many times larger than the stabilising surfactants or particles, and measures the forces as it is pushed along. This limits how sensitive measurements can be and can damage or disturb the interfacial structure. The contactless technique instead pushes on the interface by flowing liquid above it (top image above) and measuring the movement of the interface by microscopy, showing liquid-like flow and solid-like elasticity (lower image above). This enables tests on delicate particle-stabilised interfaces, including those that are of interest when reformulating products with sustainable alternatives to hydrocarbon-derived surfactants.

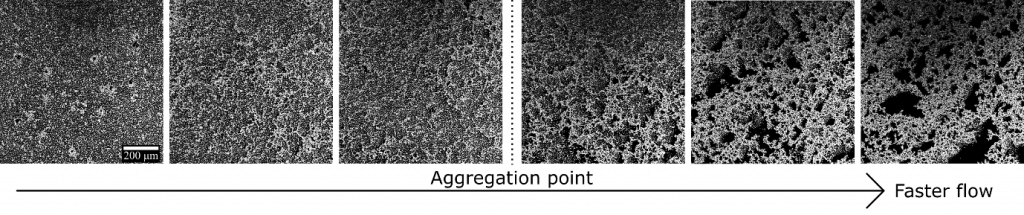

The work of Iain Muntz, led by Dr Job Thijssen and in collaboration with Dr James Richards, recently published in the Journal of Rheology and featured in a Scilight (Science Highlight), reveals that a model hard-particle stabilised interface aggregates above a critical stress (below). This leads to a weakened structure that has dramatic implications for Pickering emulsion stability.

To explore what interfacial rheology can do for your formulation challenges, please get in touch.

Our typical sample is a layer of oil on top of a layer of water, with micron-sized particles attached to the interface between the water and the oil layer. We then rotate the upper (oil) layer in a controlled manner and we measure the response of the particle-laden water-oil interface using a microscope. As we control the rotation of the upper (oil) layer, we can calculate the stress (force per unit area) applied at the interface. From the microscopy videos, we can extract the strain (deformation) of the interface in response to that stress. Hence, we can quantify the mechanical properties of the interface in a flow curve (plot of stress vs shear).

Please get in contact with us to find out more about ECFP and whether we can help you.

ECFP delivers fundamental product insight enabling improved formulation and processing for a more sustainable future.