How can we help you?

Please get in contact with us to find out more about ECFP and whether we can help you.

Waste streams from industrial processes can often contain components brimming with potential for re-use. Over the last decade or so, there has been a huge focus on transforming this “waste” into novel products to create a more circular economy, with many exciting innovations taking place within this space.

During the transformation of any waste stream, it’s common to be dealing with some form of a complex fluid. By characterising its underlying structure, innovators can understand their product’s behaviour during manufacturing and optimise its final properties to suit consumer needs and preferences. This can be particularly critical when moving up from lab to pilot to production scale.

Arda Biomaterials Ltd is a London-based start-up founded with the aim to make novel biomaterials from waste feedstocks. Their first innovation, New Grain™, is a plastic- and animal-free leather alternative made from brewers’ spent grain (BSG), a by-product of the beer brewing process that’s naturally rich in protein. Having recently opened up a new facility on the Bermondsey Beer Mile in London, the company is growing their production capabilities and working towards making New Grain™ commercially available.

For Arda, characterisation of their protein-rich BSG solution is important as its underlying properties are closely linked to the look and feel of the final leather-like material.

ECFP supervised two undergraduate physics students to work on 8-week long summer projects with the company. The summer project scheme is supported by the School of Physics & Astronomy at the University of Edinburgh, where ECFP is based, and enables companies to engage with enthusiastic 3rd and 4th year students keen to gain experience of working on research with direct relevance to industry.

After meeting with the company to discuss their needs and interests, ECFP proposed two projects that focused on characterising the properties of the BSG solution itself as well as characterising how it dries into the final product. This would give Arda crucial insight towards maximising the mechanical properties of their leather-like materials.

A variety of experimental techniques were used during the two projects, including:

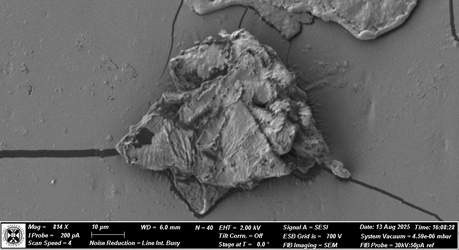

● Scanning Electron Microscopy (SEM), which provides insights into surface morphology and how this changes over time.

● Optical Coherence Tomography (OCT), which uses light to create 3D images of samples up to a few mm penetration depth. The technique is contactless and non-destructive, so these cross-sectional images can be taken over a number of time points to reveal changes in structure and composition.

● Dynamic Differential Microscopy (DDM), which can be used for assessing particle size within a sample. ECFP scientists have considerable expertise in adapting this technology for use in different systems to overcome issues such as sample haziness or viscosity.

● Tensile testing, which assesses the mechanical properties of a material using a Universal Testing Machine (UTM).

Working with the two students and the wider ECFP team provided a wealth of insight for the scientific team at Arda. At the onset of the liquid characterisation project it was already suspected that the protein solution contained some degree of lignocellulosic particulates, microscopic pieces of grain, small enough to have evaded the existing purification steps. The project confirmed the existence of these particulates and gave some characterisation of both their size and count both through optical microscopy methods and DDM. Furthermore, a previously unknown particulate impurity in the protein solution, calcium oxalate or ‘beer-stone’ was identified and also characterised.

Within the film-drying project some crucial insight was afforded into the mass evolution over time. It had previously been assumed that sample mass would decrease linearly with water evaporation from the protein slurry however the ECFP team showed experimentally and confirmed with theoretical understanding that a two-regime drying profile existed.

Together these projects will allow Arda Biomaterials to create a faster drying, more consistent final product, significantly helping in their journey to replace plastic-based synthetic leathers, a significant source of environmental microplastics.

Please get in contact with us to find out more about ECFP and whether we can help you.

Case Study – Aqualution Systems Ltd

Case Study – Lamellar Biomedical