Controlling texture through ice crystal growth in meat substitutes

Case study – Quorn Foods

Coatings are applied across a wide range of sectors including inks, paints, foods and agrochemicals. Many of us will be familiar with the dark ring of coffee stains which arise because circulation within the fluid draws suspended particles towards the edge where the evaporation rate is highest. For commercial coatings, formulation chemists incorporate additives to prevent particle migration so that the coating appears even.

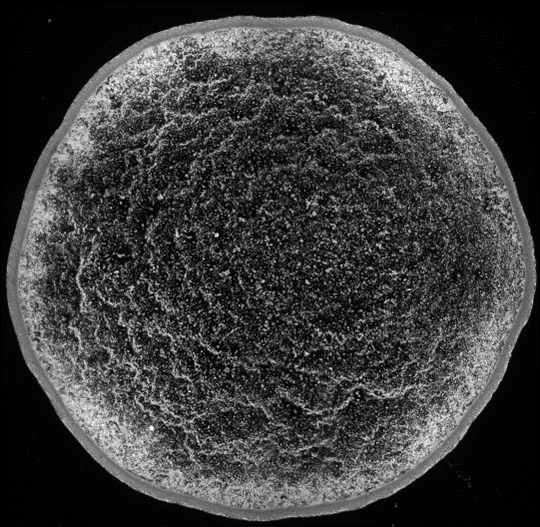

In the case of spray-on pesticides and herbicides, the microstructure of the deposit influences the absorbance of the active ingredient into the leaf cuticle. Careful formulation is required to ensure the active ingredient has optimum efficacy.

Croda are a global chemicals company who manufacture specialty functional chemicals for the agrocare, personal care and home care markets. For the agrocare market, Croda produce bespoke rheology modifiers and adjuvants for controlling and enhancing the delivery of active components (herbicides, pesticides etc.) into plants. A current research theme in this area is the investigation of how these adjuvants – chemicals added to enhance the efficacy of an active ingredient in a formulation – affect the deposited microstructure on plant leaves and how this can lead to better or worse uptake of the active into the leaf.

It is important to understand the distribution of actives during the drying process after a pesticide suspension has been applied to a leaf. Through understanding the microstructure of a formulation as it is deposited and then dries on a leaf, one can begin to understand the physical mechanisms by which adjuvants affect efficacy. The interaction of a coating with the topology of a leaf and the influence of environmental factors such as humidity and heat introduce further complexity. With knowledge of the factors that govern the distribution of actives under application, formulations can be designed and optimised.

Through two industrial placements funded by the Scottish Universities Physics Alliance (SUPA), Drs Joe Forth and Matthew Reeves, working under the supervision of Drs Job Thijssen and Tiffany Wood at ECFP, developed experimental techniques to quantitatively characterise deposit microstructure using microscopy and image analysis. Algorithms applied to images of deposits produced key parameters that correlated with the company’s internal knowledge of efficacy. The company adopted the protocols and algorithms for internal use so that they could explore the effect of a broader range of chemicals within their research and development facilities worldwide.

Please get in contact with us to find out more about ECFP and whether we can help you.

Case study – Quorn Foods

Case study – Surfteic

ECFP delivers fundamental product insight enabling improved formulation and processing for a more sustainable future.