How can we help you?

Please get in contact with us to find out more about ECFP and whether we can help you.

Meat substitutes are rising in popularity due to increased public awareness of the environmental, health, and animal welfare costs of meat production and consumption. They offer convenience and familiarity to the consumer without the need to switch to an entirely plant-based diet, but achieving a taste, texture, and mouthfeel that resembles meat can be a problem.

Quorn Foods is a subsidiary of Monde Nissin – a global food company who own many well known brands. Quorn was purchased in 2015 for £550m and their popular mycoprotein-based meat substitute products are commonly seen in supermarket aisles. They are continuing to develop new Quorn choices for their customers around the world, with several new products launched in 2019.

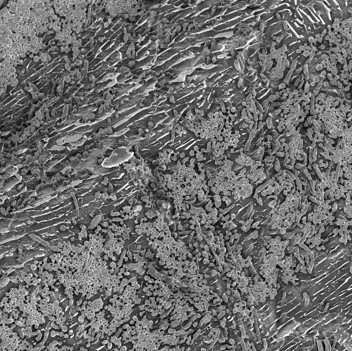

Quorn products achieve their meaty texture and mouthfeel partly through a freezing process during production. Ice crystal changes causes the mycoprotein filaments to align and with the correct spacing, this starts to resemble the fibrous texture of meat. Quorn Foods scientists were interested in better understanding this process to inform ongoing product development and wanted to explore how freezing method and duration affects the ice crystals.

ECFP researchers have expertise in several different imaging techniques and worked with Quorn scientists to determine the best method to examine the ice crystals in mycoprotein and mycoprotein based products. Cryo-SEM was chosen and small volumes of the product at different stages of the freezing process were fractured and then sublimed to partially etch the ice and reveal the grain structure. These samples were then imaged so that the ice crystal size, shape and distribution could be observed and compared between samples. The results were useful for Quorn Foods and they have expressed interest in a follow-up with new samples to test.

Please get in contact with us to find out more about ECFP and whether we can help you.

ECFP delivers fundamental product insight enabling improved formulation and processing for a more sustainable future.