Controlling texture through ice crystal growth in meat substitutes

Case study – Quorn Foods

The COVID-19 pandemic saw demand for hand sanitisers grow dramatically. Alcohol has long been used as the active ingredient in this product but can be harsh on the skin and toxic if misused (e.g., accidental ingestion). A potential candidate to replace alcohol is hypochlorous acid (HOCl). This weak acid is an extremely effective biocide and is produced naturally by our immune systems to kill harmful microorganisms and fight infections. It can also be manufactured artificially using water, food-grade salt, and electricity, meaning it is gentle on the skin and biodegradable. Together, these properties make HOCl highly suitable for use within gel hand sanitisers.

Aqualution Systems Ltd are the global leader in the science, production and application of hypochlorous acid. They are the only company able to manufacture hypochlorous that remains stable once opened and their products have been validated by EU biocide regulators, with proven kill rates of 99.9999% against pathogens.

Aqualution were looking to fulfil the global demand for hand sanitiser and partnered with ECFP to formulate a hand sanitising gel using hypochlorous acid as the active ingredient. Such gels need to remain stable over extended periods of time but dry within a few seconds after use, have suitable flow properties to prevent losses during production and use, have adequate shelf-lives and of course, efficiently kill bacteria and viruses. The aim of the project was to develop a gel formulation with HOCl that met these criteria.

We're a small team that can make a big difference. We feel strongly about leading positive change in health and hygiene and championing products and systems that drive lower infection rates, prevent cross-contamination in our food chains and can protect the environment.

Creating a gel from hypochlorous acid was a major challenge as the down side of the molecule being so effective as a biocide is that it is notoriously difficult to co-formulate it with anything else. The University of Edinburgh’s team of researchers and support staff understood our business mission and vision. Working with them and industry partners, it took over 18 months of development to create the world’s first effective hypochlorous gel which is now being sold as an alternative to alcohol sanitisers and for use in skin and pet care.

The Business Insider Made In Scotland award recognises Aqualution’s position as the leader of hypochlorous acid science and manufacture. We are an innovative company committed to solving real-world problems and making a difference and we are delighted to have our gel recognised in this way.

Funding for the project was secured from the University of Edinburgh’s EPSRC Impact Acceleration Account as a part of the Rapid Response initiative to tackle challenges arising due to the COVID-19 pandemic. ECFP first carried out a literature review to determine which gelling agents would be worthwhile testing. From here, protocols were developed to formulate HOCl-based sanitiser samples to test in the lab using 10 different gelling agents.

ECFP performed steady shear rheology measurements to determine the flow behaviour of the gels. Understanding and characterising this behaviour is key to developing a final product that can be bottled and transported but retain a suitable viscosity and drying time upon application. The stability of the gel formulations, both chemically and physically, was also assessed over a period of days to months.

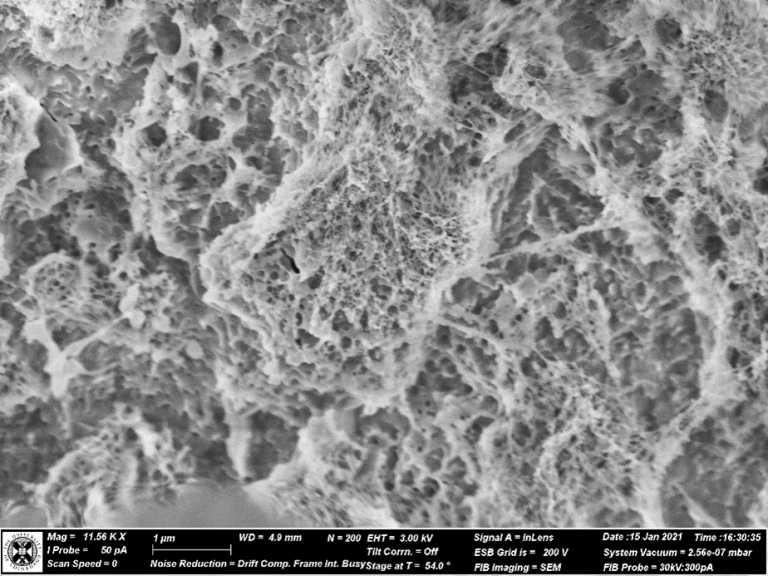

Cryo-FIB-SEM was used to examine the gels’ surface structure (below) and polymer networks. Finally, colleagues at the Roslin Institute carried out virucidal experiments using influenza and herpes viruses. These determined the minimum concentration of HOCl needed in a formulation to retain effective biocide properties.

The knowledge gained during the project helped guide Aqualution to a suitable gelling agent for their formulation. This has enabled the company to launch a new product to market: Salvesan Skin, the first gel hand sanitiser produced using hypochlorous acid.

The hand gel is also approved in the UK for use as a hand sanitiser by the Health and Safety Executive (HSE) and gained Article 55 derogation for use as a PT1 hand sanitiser, being the only hypochlorous based hand sanitiser authorised to be sold in the UK. The product is also Halal-certified.

Salvesan Skin hand gel has been used by the NHS for booster vaccinations clinics where it is at the forefront of keeping patients safe in Wiltshire via the Sarum Cathedral Primary Care Network, made up of Harcourt Medical Centre and Salisbury Medical Practice. The Network dispensed Salvesan Skin via Gelpoles to over 25,000 patients in October and November who were attending the clinic for their Covid-19 boosters.

Recognising that Salvesan’s HOCl-based gel innovation is spearheading a revolution in infection control, the product has won Aqualution a national prestigious award at the Business Insider Made In Scotland awards, for Best New Product. This award is for a new product designed and/or manufactured in Scotland and put on the market from November 2020 to December 2021 which has the potential to drive significant new sales. The award ceremony was held on Thursday 19th May 2022 at the Glasgow Science Centre, sponsored by Scottish Business Insider and the National Manufacturing Institute of Scotland.

Please get in contact with us to find out more about ECFP and whether we can help you.

Case study – Quorn Foods

Case study – Surfteic

ECFP delivers fundamental product insight enabling improved formulation and processing for a more sustainable future.