DAINTech

Dispersions Arrested in Nematic (liquid crystal) Technology: DAINTech

Dispersions Arrested in Nematic (liquid crystal) Technology offers a new way to create stable formulations with appealing sensory properties without using polymers.

We encourage you to get in contact with ECFP if you are interested in finding out more about this technology or would like to know about licencing options.

About DAINTech

DAINTech is an innovative new gel phase formulation chassis technology that offers long-term stability; unique and beneficial flow characteristics; and is ecologically responsible due to the absence of synthetic polymers.

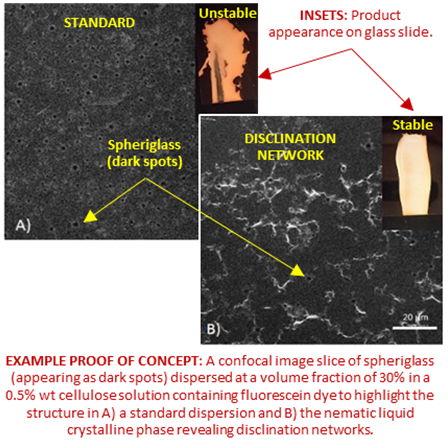

The images show how DAINTech offers a smooth and stable coating (right) compared to its non liquid crystalline equivalent formulation (left). A summary of its enhanced property offerings include:

- Sustainable formulation – direct substitute for polymer-stabilised formulations

- Stable suspension

- Smooth coating

- Highly shear thinning

- Tunable yield stress

Technology Overview

As their names suggests, liquid crystals possess properties that lie between liquids and solid crystals. While their molecules are not tightly packed (allowing them to flow like a liquid), they are aligned in a way that results in orientational order, as in a solid crystal. For example, in the so-called nematic phase of a liquid crystal, molecules are orientated in parallel but not in well-defined planes.

Adding colloidal particles to these liquid crystals will disrupt their orientational order and generate defect lines called disclinations. Soft matter scientists from the University of Edinburgh have discovered a new class of stable soft solids by dispersing high concentrations of colloidal particles in a nematic liquid crystal. This stability arises from the defect lines, which are connected and entangled throughout the nematic phase. The lines carry a tension that restricts the nematic phase to small monodomains, enhancing viscosity and forming a strong gel without the need for any shear. Once this gel yields, the viscosity approaches that of the background liquid crystal.

These unique properties make DAINTech a disruptive and innovative technology for formulation scientists. It has excellent stability against sedimentation (and in some cases, high temperatures), a unique sensory performance (highly shear thinning but recovers elasticity when shear ceases), and a tuneable yield stress. DAINTech can produce smooth coatings, prevent the growth of bacteria, and provides a mechanism for selective delivery of actives to surfaces. Finally, it enables formulators to avoid the use of polymer stabilisers and therefore a route to creating greener products.

A range of dispersions based on DAINTech, up to 1kg in weight, have been made in our laboratories using industrial colloids (spheriglass 3000 and 5000, titania, calcite, cornflour and sunflower oil) and aqueous and non-aqueous solvents. We are keen to collaborate with industry to develop new and unique formulations using this technology.

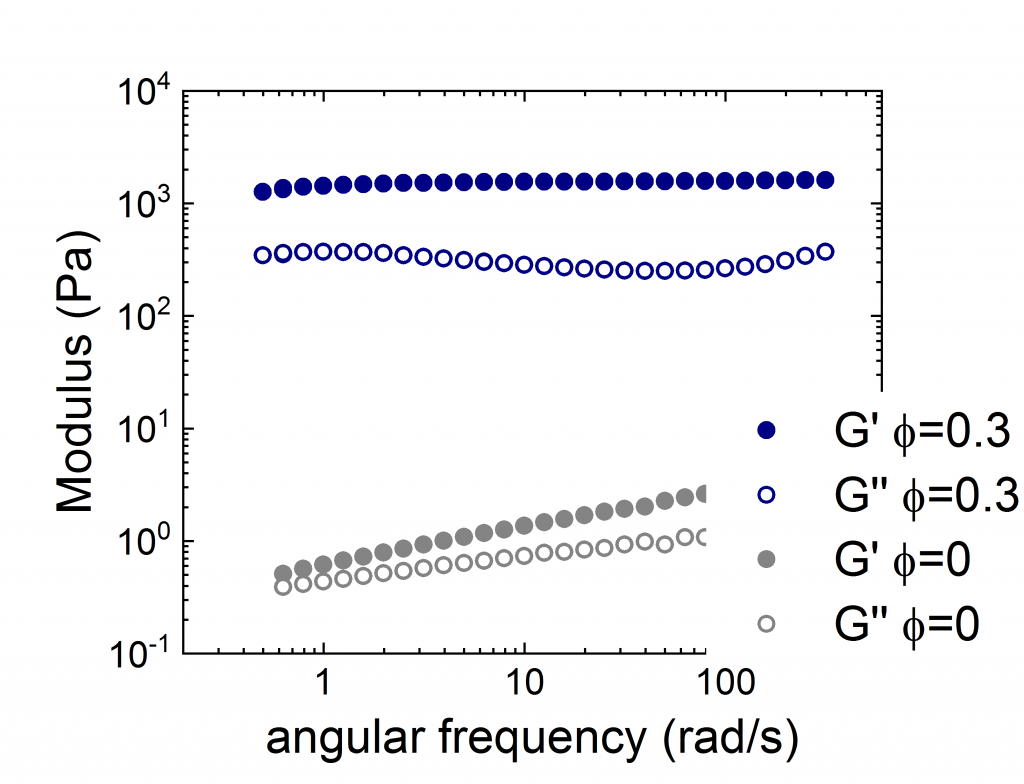

The image above is shows the difference in rheological properties between DAINTech (blue) and its equivalent formulation without the liquid crystalline defects (grey). DAINTech is highly elastic, reflected by a higher G’ (storage modulus) than G” (loss modulus). The increase in modulus by over three orders of magnitude compared to its non liquid crystalline equivalent implies it is highly stable and may provide an extended shelf life.

Application Areas

DAINTech can be used in a range of application areas including:

- Personal care

- Coatings and paints

- Speciality chemicals

- Pharmaceuticals

Publications & Patents

The underpinning science of DAINTech is published in several peer-reviewed journals:

A Self-Quenched Defect Glass in a Colloid-Nematic Liquid Crystal Composite

T. A. Wood, J.S. Lintuvuori, A. B. Schofield, D. Marenduzzo & W. C. K. Poon. Science 334, 79-83 (2011).

The Yielding of Defect-Entangled Dispersions in a Nematic Solvent

N. Katyan, A. B. Schofield, T. A. Wood. Journal of Rheology 65 (6), 1297-1310 (2021).

We currently have a Granted USA patent and an EP patent application.

Defect Mediated Lyotropic Nematic Gel

T. A. Wood, N. Katyan, US 12,012,541 B2 (2024)

Licensing

DAINTech is available for commercial licensing and/or co-development. To make a direct enquiry about licensing DAINTech or to find out more about how this technology might be used in your products, please use the buttons below:

Additional Capabilities and Formulation Support at ECFP

How can we help you?

Please get in contact with us to find out more about ECFP and whether we can help you.