Applications

Our cutting-edge research delivers fundamental insight into product design and process

Applied Research

Our scientists study the fundamental physics that governs how components (such as colloids, polymers, liquid crystals etc.) interact with one another in complex fluids. The themes below are areas of strength where we can use our expertise to support industry.

Sustainability

Sustainability is an increasingly important consideration across all sectors of industry, with increasing consumer awareness, government legislation and volatile energy costs necessitating improvements to the efficiency and robustness of products, processes, and supply chains. ECFP’s expertise in formulation science and soft matter characterisation helps companies identify where such improvements can be made by providing a fuller understanding of the physical mechanisms underpinning product manufacture, stability and performance. We are particularly interested in assisting industrial partners to reformulate their products using more sustainable ingredients, especially those products currently using petrochemical-derived surfactants and polymers.

Formulation Science

Formulations surround us in our everyday lives, from cosmetics and cleaning products, to paints and coatings, agrochemicals, pharmaceuticals, and fuels. Understanding the physical interactions between the individual components that make up formulated products is key to controlling their behaviour, improving performance, and addressing manufacturing challenges.

ECFP scientists specialise in applying the principles of soft matter physics to formulations and have extensive experience of working with industrial partners to develop solutions for problems relating to formulated products. A more complete understanding of the physical principles underlying formulation behaviour also creates opportunities for innovation, for example, through the introduction of new or more efficient processing methods or a reduction in the number of product ingredients.

Highly concentrated suspensions of particles in liquids are known as dense suspensions. They are found across a wide variety of industrial applications including batteries, slurries, paints, cement, drilling fluids, and food products. ECFP scientists have significant experience exploring the jamming, yielding and flow of these suspensions, using confocal microscopy with simultaneous rheological measurement to study their flow. These experiments give important new insights into product flow behaviour, and help bring about improvements to their processing and transport.

While rheology involves the study of the flow of matter, tribology is concerned with the friction, lubrication and wear of interacting surfaces. ECFP can provide a combined understanding of these two states (“triborheology”) to illuminate product behaviour over time, from initial pouring of a thick layer (rheology-dependent) to spreading of an increasingly thin layer over a surface (tribology-dependent).

We can also provide insight into how the desired sensory properties of products are linked to their response to the applied shear stresses and strains experienced during their use. This can reveal ways in which to optimise these properties through manufacturing processes.

Many consumer products consist of colloids dispersed with other ingredients such as polymers, surfactants and nanoparticles. The presence of these smaller species can cause aggregation through the depletion mechanism, leading to separation and the formation of a liquid layer above a sediment. Another aggregation route is the bridging mechanism, where sticky polymers adhere to particles causing flocculation and sedimentation. In both cases, the product’s resulting appearance is undesirable for consumers. ECFP researchers can determine the root mechanisms behind dispersions displaying aggregation or sedimentation and provide solutions to ensure a stable final product.

We have a strong interest in interface stabilisation and interfacial rheology and destabilisation. Using surfactants, polymers, particles and proteins, we can design and produce emulsions with specific sensory aspects, multiple emulsions and bijel microcapsules with the potential to protect and deliver active ingredients. Structures can be tailored for triggered release by pH, temperature or shear and can be fabricated with food grade materials. We are also interested in using our expertise in this area to assist industrial partners in reformulating products to minimise the use of petrochemical-derived surfactants and polymers.

High performance materials with conductive or responsive properties are often made by incorporating particles with other components such as polymers, surfactants and colloids. Interactions between the particles and the other components influence the microstructure of product and the flow behaviour. By working to understand these interactions, ECFP can help improve processing performance and optimise the performance of these materials.

Other commercial products use polymers in solution, for example, as a yield stress fluid or as a binder in an extruded product. We blend theoretical understanding with rheological measurements to understand the relationship between intrinsic relaxation times, process shear rates, and material behaviour. This is often vital for optimising the manufacturing process.

Advanced Materials

Many of today’s advanced materials are processed in a wet or molten state in which complex fluid behaviour determines the microstructure and properties of the final product. Design principles and discoveries from soft matter physics therefore enable ECFP to contribute to the development of such materials, which can be tailored to have unique capabilities for many different industrial sectors ranging from energy applications to biomedical devices. Scientists at ECFP are involved in the development of several advanced materials, including bijels, liquid crystal-stabilised suspensions (DAINTech), and DNA-based materials. There is considerable potential to create new products with remarkable properties using these materials and we are keen to work and innovate with industrial partners to realise this exciting goal.

ECFP can help companies understand the effect of various processing routes (for example, shearing) on product microstructure and rheology. In this way, manufacturing steps and transportation protocols can be altered to improve the properties of materials used in industrial applications ranging from controlled porosity and strength tissue scaffolds to high strength concrete formulations with desirable flow behaviour.

Bicontinuous interfacially jammed emulsion gels (“bijels”) are a novel soft material originally proposed and then experimentally realised by soft matter scientists at the University of Edinburgh. They are formed by dispersing colloidal particles at the interface of two immiscible fluids, jamming their separation and creating a stable, bicontinuous structure. Bijels have a number of application areas. Their large interfacial surface area within a relatively small volume is particularly useful for catalysts and electrodes for batteries and fuel cells. Other uses for bijels are scaffolds for tissue engineering, filtration devices, controlled release agents, cross-flow microreactors in chemical engineering and separation processors.

DNA is a long-chain double helical polymer. Like all polymers, these chains can become entangled at high concentrations. Specialised proteins are able to change the shape or “topology” of DNA to remove these entanglements – for example, splitting and reforming a chain – allowing for chromosomes (long pieces of DNA) to be read, copied and distributed to new cells during cell division.

When DNA molecules are divided and rejoined, it is critical that the original genetic sequence is maintained otherwise cells can die or diseases develop. As a result, the topological operations performed by these proteins must happen at exactly the right place and time – in biological terms they are “regulated”. Polymer and statistical physicists from ECFP’s academic team are using computational and experimental methods to artificially reproduce this process to create a new generation of “topologically active” DNA-based complex fluids and materials.

By harnessing topology altering proteins, these materials would combine the information-storing properties of DNA with the ability to respond to external stimuli and change their properties over time. This opens up exciting applications, from drug delivery and cellular scaffolds to sensing devices.

Dispersions Arrested in Nematic (liquid crystal) Technology offers a new way to create stable formulations with appealing sensory properties without using polymers.

As their names suggests, liquid crystals possess properties that lie between liquids and solid crystals. While their molecules are not tightly packed (allowing them to flow like a liquid), they are aligned in a way that results in orientational order, as in a solid crystal. For example, in the so-called nematic phase of a liquid crystal, molecules are orientated in parallel but not in well-defined planes.

Adding colloidal particles to these liquid crystals will disrupt their orientational order and generate defect lines called disclinations. Soft matter scientists from the University of Edinburgh have discovered a new class of stable soft solids by dispersing high concentrations of colloidal particles in a nematic liquid crystal. This stability arises from the defect lines, which are connected and entangled throughout the nematic phase. The lines carry a tension that restricts the nematic phase to small monodomains, enhancing viscosity and forming a strong gel without the need for any shear. Once this gel yields, the viscosity approaches that of the background liquid crystal.

These unique properties make DAINTech a disruptive and innovative technology for formulation scientists. It has excellent stability against sedimentation (and in some cases, high temperatures), a unique sensory performance (highly shear thinning but recovers elasticity when shear ceases), and a tuneable yield stress. DAINTech can produce smooth coatings, prevent the growth of bacteria, and provides a mechanism for selective delivery of actives to surfaces. Finally, it enables formulators to avoid the use of polymer stabilisers and therefore a route to creating greener products.

A range of dispersions based on DAINTech, up to 1kg in weight, have been made in our laboratories using industrial colloids (spheriglass 3000 and 5000, titania, calcite, cornflour and sunflower oil) and aqueous and non-aqueous solvents. We are keen to collaborate with industry to develop new and unique formulations using this technology. Further information on DAINtech can be found here.

Skin Science

In both the cosmetic and medical sectors, topical delivery normally involves the spreading and massaging of a soft material onto the skin. It is therefore important to consider the physical interactions governing this biological system in order to optimise product performance. ECFP can help companies understand how their products interact and permeate the skin, formulate novel skin-based products (for example, hand sanitisers), and test product efficacy and sensory properties. Through the university-wide “EdSKiN” network, we have access to additional expertise from colleagues working in biology and chemistry, giving significant scope for interdisciplinary collaborations in this area.

There are a range of experimental models available for skin research ranging from synthetic substrates to organotypic to ex vivo mammalian skin, of which we have facilities for storage and handling of. Depending on the problem in question, we can advise on the most appropriate model. In addition, ECFP has previously worked on computational approaches to support skin-related research.

ECFP uses its expertise in physical characterisation to further understand the biophysics of skin. For example, one of our current interests is understanding how the skin responds to environmental exposure. A thorough characterisation of the skin enables us to understand how the skin responds or changes to the presence of external agents such as cleansing agents and pollutants. Monitoring the changes in skin can lead to understanding the mechanisms of interaction present. Furthermore, it can enable us to understand the causes to skin damage and how we can reduce and prevent the extent of damage, for example, by developing more skin friendly hand sanitisers.

Using our biological expertise and capabilities, ECFP can explore how particular ingredients, formulations, or products interact with the skin microbiome. Using the model skin methods described above, we can study transient, resident and biofilm-forming bacteria, and we have close links with the National Biofilm Innovation Centre (NBIC) who are also active in this area.

Food & Drink

Soft matter physics gives insight into the structure, processing and stability of a wide variety of foods. ECFP can help companies understand the roles of certain ingredients in recipes and formulations and allow manufacturers to tune their recipes to achieve a range of perceived benefits without damaging any of the distinctive properties of the product (for example, reducing fat without compromising mouthfeel or lowering sugar content without impacting texture). We have strong connections with Scottish Food & Drink and are particularly interested in engaging with SMEs who are looking to develop a deeper understanding of the science underpinning their food products.

Cleaning & Disinfection

The interactions and behaviour of microorganisms such as bacteria and viruses in complex fluids and on surfaces can be modelled and studied using soft matter principles and techniques. ECFP has an excellent research base in biophysics, biofilms (communities of microorganisms that stick to each other and to surfaces) and the physics of active matter (for example, the bacterium Escherichia coli), along with strong complementary links with the National Biofilm Innovation Centre. By understanding their fundamental biology and physics, we want to control harmful microorganisms or harness them for our own benefit. We can help companies design novel cleaning products and techniques and understand the key mechanisms behind product efficacy in order to maximise disinfectant capability.

A specific area of our expertise concerns the interaction between bacteria and the viruses that prey on them, known as bacteriophages. As these viruses can kill bacteria without any negative effect on human or animal cells, they are a promising alternative to current commercial disinfectants, and could be used to eliminate bacterial and biofilm contaminations in settings such as hospitals or food packaging.

The emergence and spread of bacterial infections that are resistant to antibiotics and other antimicrobials is one of the most urgent global health issues. We use laboratory growth and evolution experiments, combined with computer simulations and mathematical theory, to understand how antibiotics affect bacterial growth under different environmental conditions (for example, rich vs poor nutrients, biofilm vs planktonic growth). ECFP scientists also study the pathways by which bacteria evolve to become resistant to antibiotics, using lab evolution experiments, DNA sequencing and mathematical modelling.

Bacteria often form aggregates in liquid suspensions or when suspended in a gel. These aggregates have been implicated in infections and, like biofilms, tend to be resistant to antibiotic treatment. Bacterial aggregates are also crucial in processes such as wastewater treatment. We use a combination of lab experiments and computer simulations to understand how the underlying physical and biological processes control the final size and spatial structure of these aggregates.

Bacterial communities, biofilms and other microorganisms structure their local environment using a range of biomolecules with interesting physical properties and behaviours. Although a diverse range of biomolecules have been identified and characterised, we have observed some commonalities in their resulting functions that may be of benefit in giving structure to soft formulations. To this end, we are interested in identifying and characterising the physical behaviour of these individual components using a range of experimental and computational tools.

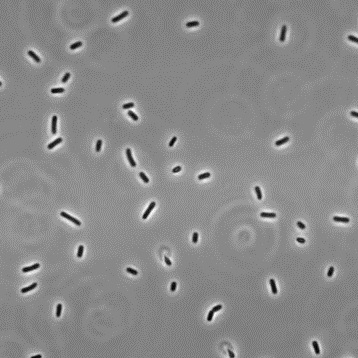

ECFP researchers have developed image analysis algorithms for quantifying the behaviour of microorganisms that allow for 1) fast measurement of the distribution of swimming speeds of a large population of microorganisms and 2) categorizing different types of behaviour. These offer convenient approaches to evaluate the effects of environmental factors such as viscoelasticity, chemicals and antagonists on microorganisms.

Water Treatment

We have a strong interest in wastewater treatment and the development of novel membranes for filtration applications, in collaboration with colleagues in the School of Engineering. Using a combination of experiments and computational simulations, we investigate collective phenomena in the wastewater treatment bacteria Comamonas denitrificans. These bacteria degrade the pollutants that are dissolved in wastewater whilst also sticking together to form biofilms and dense aggregates. As the aggregates settle under gravity, they can be separated from the remaining liquid. We are developing model systems that help industry optimise the functionality of these bacteria as well as exploring the possibility of using C. denitrificans to reduce the levels of greenhouse gas emissions generated during the wastewater treatment process.

Instrument Development

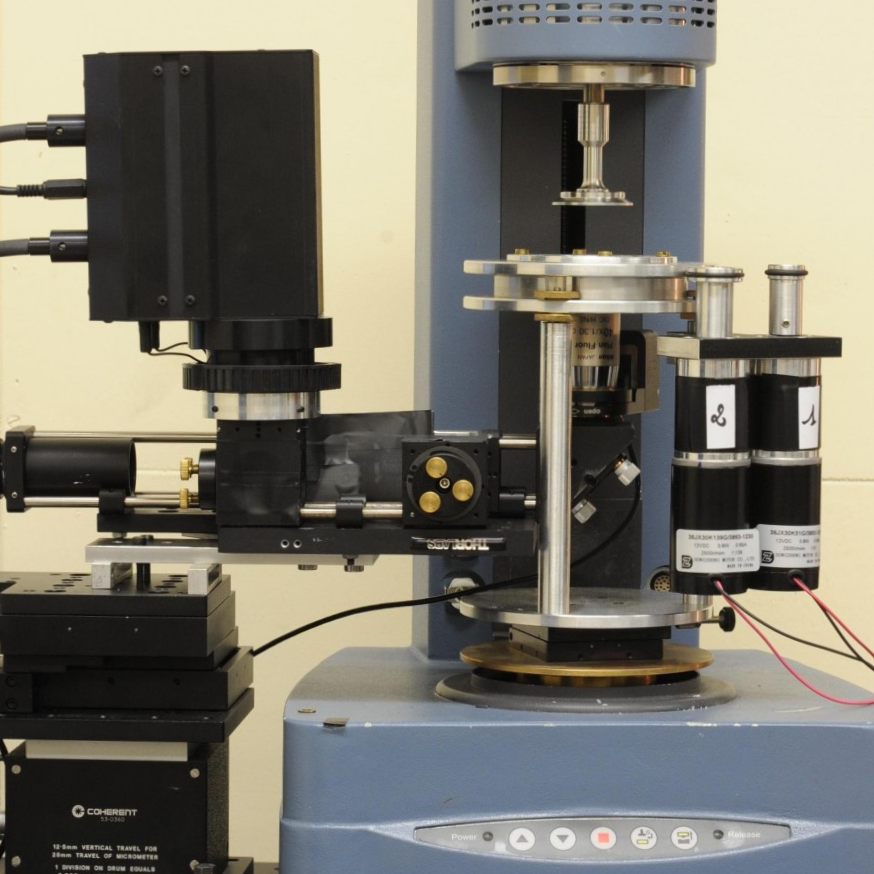

ECFP has considerable optomechanical and computer programming expertise that we use advance our measurement capabilities and support our research into soft matter systems. We have previously developed a rheoimaging module for standard rheometers and the technique of Differential Dynamic Microscopy to characterise the motility of microorganisms such as algae and bacteria. Read more about our equipment and capabilities and please get in touch if you have a soft matter measurement need that we design a solution for.

ECFP scientists have developed a rheo-imaging system

consisting of a fast confocal microscope (up to 100 fps) coupled to an

Anton-Paar rheometer. This instrument measures the rheological

response of materials while simultaneously imaging the corresponding changes in

microstructure. In this way, the macroscopic properties of products and

formulations can be linked to their microstructure and dynamics, offering a

deeper insight into product behaviour.

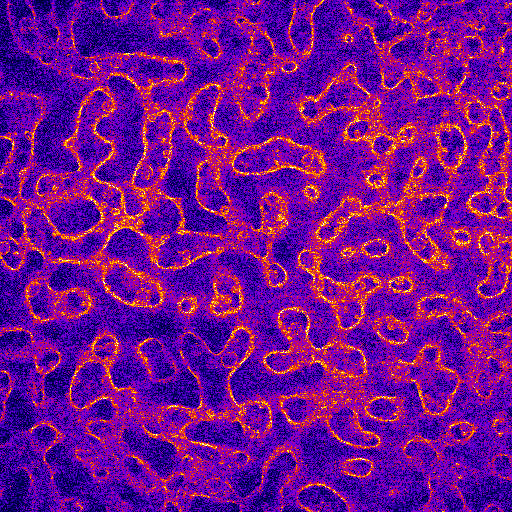

Differential dynamic microscopy is an imaging technique that characterises the dynamical properties of colloidal suspensions over a wide range of particle concentrations. In particular, DDM can be used to study the behaviour of both swimming microorganisms (e.g., bacteria and microalgae) and artificially propelled microscopic swimmers (e.g., Janus particles). Using low-magnification images from standard microscopy, DDM can quickly determine changes in the motility of large populations these microorganisms in response to stimuli, anatagonists or environmental conditions. ECFP scientists have been extensively involved in the development of this useful technology and have significant expertise in adapting it for use in a variety of different systems and microswimmers.